Valves for Gas Processing and LNG

Global operators trust Ladish Valves for energy processing, including gas, liquefied natural gas (LNG), and other cryogenic applications. We engineer and test our valves according to various industry standards.

Built for Low Temperature

Environments

The production, transport and storage of liquefied gases such as oxygen, nitrogen, natural gas (down to –425°F) demand a thoughtful solution. Key features of our low temperature valves include:

Adhere to Demanding Standards

Our stainless steel cryogenic valves are produced to the rigid ‘Controlled Quality’ standards that assure dependable operating performance at sub-zero temperatures.

Cryogenic readiness

We design cryogenic valves specifically to handle the extreme temperatures required for LNG. Cryogenic manufactured in accordance to BS 6364, MSS SP-134 is available at our Houston headquarters.

Cold box vs non cold box

Optional non-cold box and cold-box designs per MSS SP-134 or BS.6364

Compliance

Ladish Valves meets all compliance requirements for cryogenic valves, including API 600, API 603, API 607, API 608, API 623, ASME B16.34, MSS SP-134, BS 6364.

In-House NDE services available

Ladish Valves stands by the integrity of our low temperature products. To ensure the best quality products reach our customers, we offer the following in-house NDE services:

Radiographic examinations enable us to assess the internal structures of our products to verify their integrity.

Liquid dye penetrant assessments help us ensure surface-level quality of the highest standard per ASME B16-34.

Ladish checks our material using PMI and adhering to strict standardsfor material conformity and chemical analysis.

We perform on-site tests to determine the level of ferrite in austenitic and duplex stainless steel, ensuring the levels don’t interfere with a valve’s strength and resistance to corrosion.

Ladish Valves QA/QC has full traceability of all our major components.

Built for Demanding Environments

Tailored valve solutions to meet exact specifications.

Designed, assembled, and tested entirely in the U.S.

Non-stock valves delivered in as little as 16 weeks.

Fast, clear communication from quote to delivery.

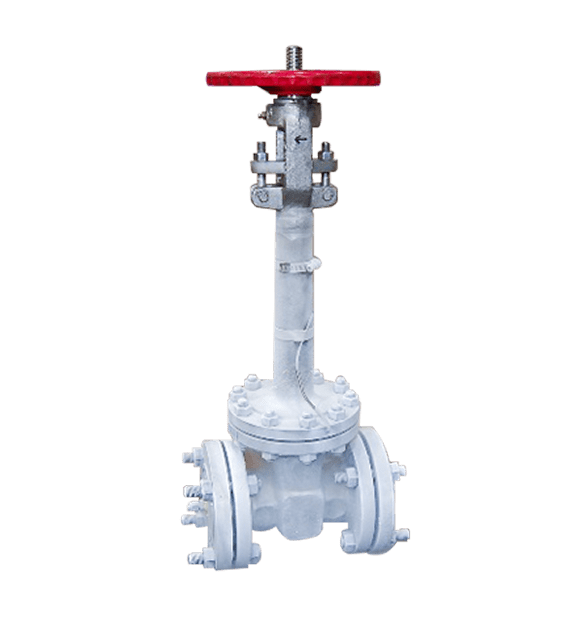

Common Valve Types of Gas Applications

Here’s a quick list of our products that are relevant for gas applications:

- Ball valves (floating and trunnion-mounted).

- Gate, globe, and check valves.

- Cryogenic valves.

- Exotic alloy and custom builds.

Ready to speak to one of our experts?

Want to learn more about the Ladish process or begin your order? Please reach out for a technical review, a quote, documentation support, or anything else.