Metal & Graphite Seated Ball Valves – Designs and Applications

Content provided by Barry Hoeffner

Metal Seated Valve Coatings

Metal seated valves represent the fastest growing (by %) segment of the valve industry. These seats can be found in ball vales, butterfly valves, plug valves and others.

- What are “Metal Seats“?

- Dissimilar Metals (Old Technology no longer widely accepted)

- Base Metal Contact (Gate and Globe Valves – Not Sliding Wear)

- Coated or Modified Metal (Most Common)

- Stellite Weld Overlay (Usually Stellite VI – Cobalt Based)

- “Surface Modification” of Sealing Surfaces: Ex. Nitriding, Boronizing, etc.

- Plating: Ex. Chromium Plating or ENP (Electroless Nickel Plating)

- HVOF Coating: Tungsten and Chromium Carbide are the most common

- Fused or Vacuum Deposition of “Coating” typically Tungsten Carbide

- There is no “One size fits all” for “Metal-to-metal” sealing. Coatings are very application dependent.

HP-HVOF Process

- Chrome Carbide, Tungsten Carbide, Chrome Oxide and other specially formulated coatings.

- Cr3C2-NiCr

- WC-Co / WC-Ni / WC-Co-Cr / WC-CrC-Ni

- Coating mechanically bonds to the Substrate Material.

- Mechanical bond – >12,000 psi bond strength for Carbides, 5,000 – 7,000 psi for Chrome Oxide Ceramic.

- Robotically positioned spray gun creates high kinetic energy allowing the coatings to be applied in a compressive state.

Spray & Fused Process – Colmonoy

- Substrate material becomes annealed due to fusing temperatures; subsequent heat treatment required.

- Semi-molten coating “sags” or “sloughs” – gravity effect

- Coated Surface is “finish” machined using either CBN (cubic boron nitride) or PCD (polycrystalline diamond) tooling.

Vacuum Testing of Valve Trim Sets Prior to Installation

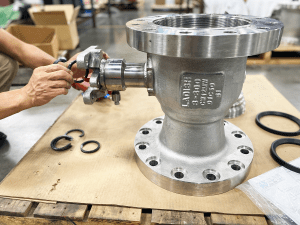

Ladish ball & seat

“Critical” Service Ball Valves – MEGA Seal

| GRAPHITE SEATED | METAL SEATED |

| Class 300 and 600 | Class 150 – 600 |

| Flanged Ends | SW/BW, RFF, RTJ End Connection Possible |

| ¾” – 8” | Inserted Seats (Repairable Design) |

| Split Body or Unibody, Full or Reduced Port | .5” – 14” |

| Target Market: Clean High Temperature and Acid Service with Temperatures above 450F (up to 1000F) | Target Market: Refining and Chemical, Severe Service

•High Temperature •Solids Handling •ETHYLENE and VCM •Alloy Options include 316SS, Monel, Inconel, etc. |

| Tight Shut-Off Capability | |

| Full Alloy Options (Hastelloy, Inconel, Incoloy, Monel, etc.) | |

Severe Service Ball Valves

| POWER VALVE | ENGINEERED METAL SEATED |

| Class 900/1500, 2500 (3100) & 4500 | Class 150 – 2500 |

| Welded – Ends (SW / BW) | SW/BW, RFF, RTJ End Connection Possible |

| .5” – 3” | Inserted Seats or Captured Flange (Repairable Design) |

| Forged (Machined from bar), 2-piece construction | .5” – 14” |

| Target Market: Thermal Power & High Pressure Steam / Hydrocarbons | Target Market: Refining and Chemical

•High Temperature •Solids Handling •Coking / Fouling Services •Automated on/off & high cycle |

| Tight Shut-Off Capability | |

Ladish “T” Series Power Valve:

| APPLICATIONS – ISOLATION, VENTS & DRAINS |

| Size: ½” – 3” |

| A105, F22, F91, F92 & others |

| Ball & Seat

•410 SS – HP-HVOF (Cr3C2-25NiCr) •Inconel 718 – Fused ((CrB – Cr3C2 ) |

| Pressure Class

•1500# – 4500# |

| Bore Sizes

•.65”, 1.00”, 1.50” (1500#, 2500#,/3100#) •.65, 1.00” (4500#) |

| 2-Piece Construction |

| Uni-directional (Std.) |

Engineered Severe Service Metal Seated Ball Valve:

I. Initial Target Applications

- Automated On/Off and High Cycle Applications

- High Temperature Isolation (Generally >600F)

- Solids Handling (eg. FCCU Catalyst, Coke Fines, Hot Gas Service with Fines)

- Gasification

- Polyethylene and Polypropylene

- Acid Leaching of Minerals

- High Pressure Steam and Boiler Feedwater in the Process Industries

II. Two “Flavors” of the Ladish Severe Service Valves

- Captured Flange” to create better resistance to High Temperature “Thermal Shock” and allow reparability.

- Inserted Seat for designs with short Face-to-Face (eg. Class 150 and 300 Flanged) and used in larger Bore (>8”) applications.

Note: Valves have a preferred sealing direction but can be configured for full bi-directional service.

Severe Service Metal Seated Ball Valve:

FCCU Critical Ball Valves:

Chrome alloy valves for temperatures to 850F, 321SS for temps to 1400F.

For more information on the MEGA Seal or Severe Service lines, please contact us! sales@ladishvalves.com or 281.880.8560. View more details on the MEGA Seal line here.

Once again, Ladish will continue To Mark Progress.

We’re Social @LadishValves