Metal & Graphite Seated Valves for High Temperature

MEGA Seal Ball Valves

MEGA SEAL OVERVIEW

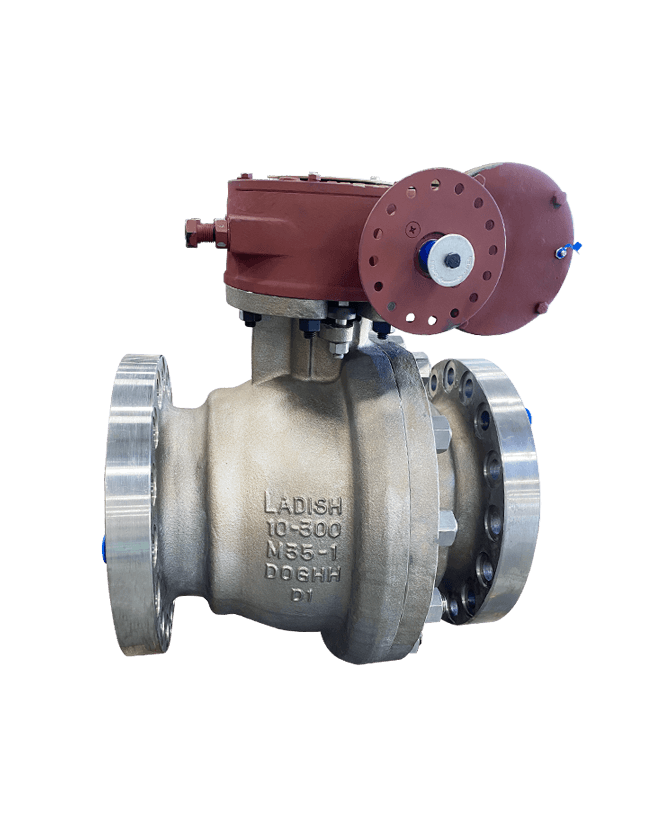

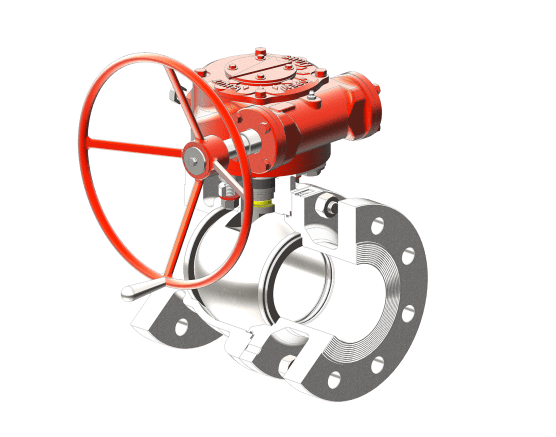

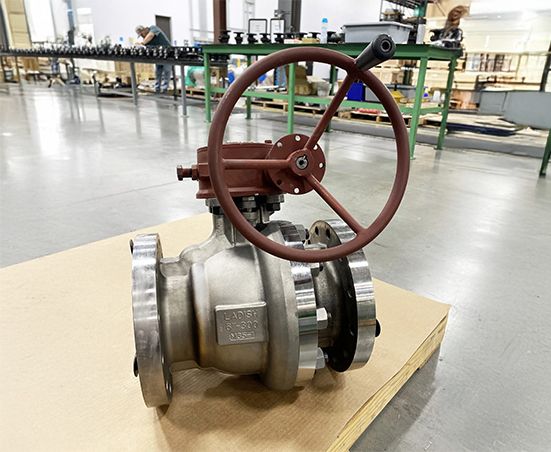

Ladish Valves MEGA SEAL is our Critical-Service Metal and Graphite Seated Floating Ball Valve line with all of the technical features needed for the more demanding Industrial Applications. Designed for Safety, Low Emissions, Long Service Life, and ease of maintenance, this series is available in Split-Body Full and Reduced Port styles as well as One-Piece (Uni-body) reduced port construction. Available in Exotic Alloys as well as more common materials, the MEGA SEAL should be your go-to choice for Critical and Toxic Services in applications where Elastomeric Seats and Seals are impossible to use or limit system reliability.

METAL SEATING

For Critical services containing solids, including those with high temperatures and pressures, Ladish recommends our Metal-Seated Ball Valve. This is a Bi-Directional Valve with graphite solids-proof gaskets between the seats and valve body. Ball and seat coatings prevent damage to erosion and galling during cycling.

- Fully captured spiral-wound graphite filled body gasket on split body designs.

- Meets ASME B16.5, B16.10 and B16.34 design.

- Locking lever or gear operator standard.

- Blowout-proof stem

- Full and standard port available

- Testing to API 598

- All ball valves assembled and tested in Houston

- Meets all requirements of API 608

- Low Emissions: API 622 certified graphite-based packing for fire-safe designs.

- “Chevron-Style” PTFE stem seal as well as dual packing configurations are available.

- Integral ISO mounting pad on cast valves for ease of automation without bracket or separate coupler.

- Internal and external stem bearings to prevent “side loads” that can cause leakage in the field.

- Live-loaded stem packing. Fully adjustable even with actuation installed.

GRAPHITE SEATING

For relatively clean High Temperature Applications, Ladish recommends our Bi-Directional, Compressed Carbon Graphite Seated valve with base metal ball.

- Fully captured spiral-wound graphite filled body gasket on split body designs.

- Meets ASME B16.5, B16.10 and B16.34 design.

- Locking lever or gear operator standard.

- Blowout-proof stem

- Full and standard port available

- Testing to API 598

- All ball valves assembled and tested in Houston

- Meets all requirements of API 608

COATING OPTIONS

This HVOF applied coating is very wear resistant and an outstanding choice for the majority of special services including Steam and non-corrosive applications. It achieves a Hardness of approximately 68 HRC and is effective up to 1400F.

This is a standard for many lower temperature (Cryogenic – 900F) abrasive applications. It is also commonly used in Automated Valves in High-Cycle Service. This HVOF applied coating achieves a hardness of approximately 72 HRC.

This is a plasma-applied Corrosion Resistant coating used in services where weak acids may be present and High Nickel Alloy valves are used. It is less erosion resistant with a HRC hardness of 60 – 65, but is recommended when ceramic-like corrosion resistance is required.