How To Choose Your Isolation Valve

For the Oil & Gas, Petrochemical & Chemical Markets

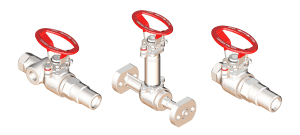

In response to the fugitive emissions concern for instrumentation valves in the industry, Ladish has designed the Instrument Isolation Valve line to meet the demand in the market. With a variety of configurations including threaded, MSWE, BWE, I-Flange, and Multi-Port, Ladish can meet your design criteria. Instrument Isolation Valves can be used in a variety of applications including vents, drains and block valves for instrument connections for pressure, level and flow measurement. Catalog 461 serves to highlight the Ladish Valves line of Instrument Isolation Valves.

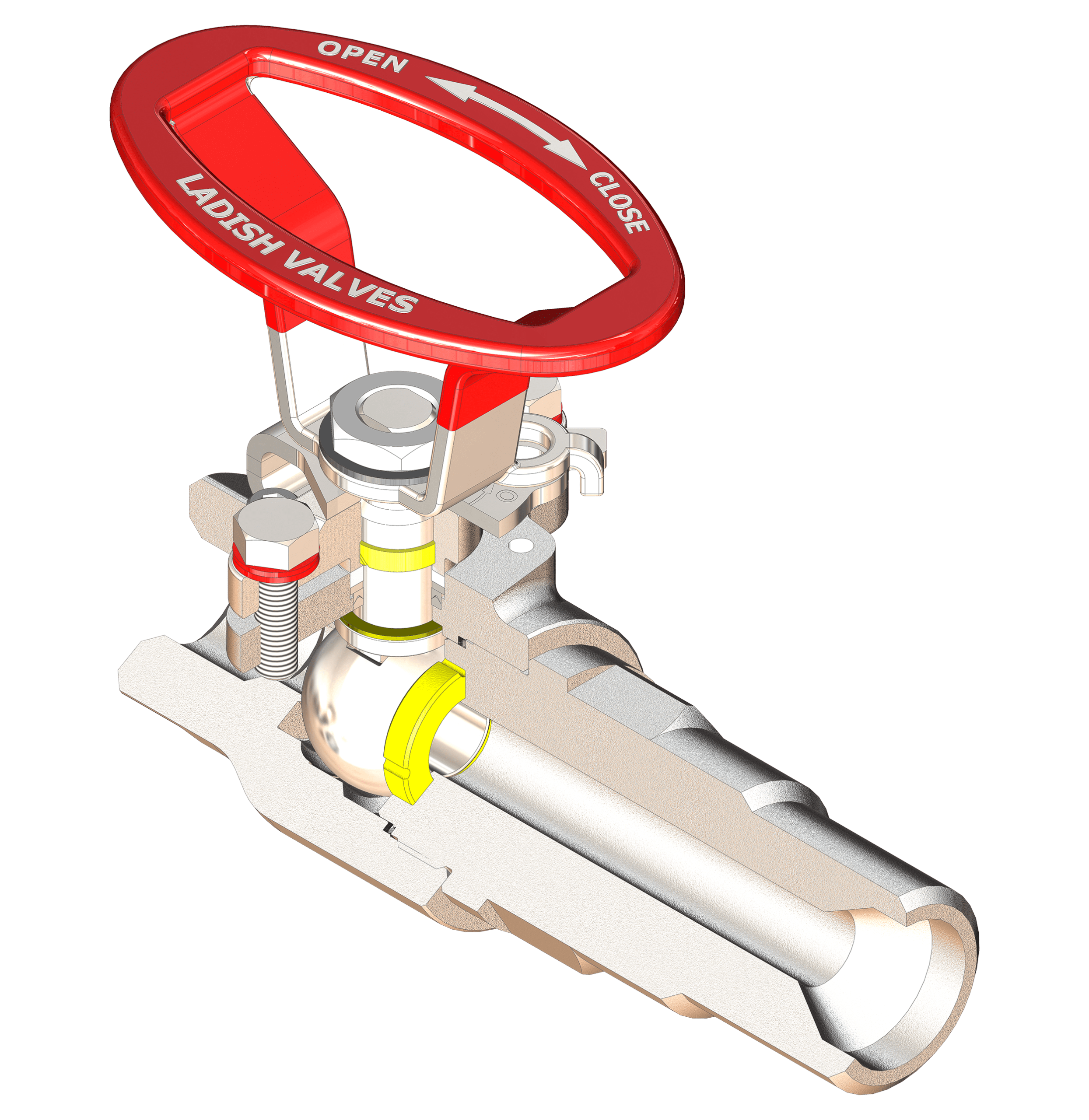

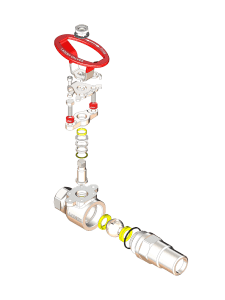

All of the Isolation Control Valve series include a wide variety of stringent features including:

- Design to ASME B16.34

- ISO5211 Mounting Pad

- API 607

- API 641

- Oval handles with visual position indicator

- Blowout proof stem

- Live-load packing

- Lockable

- Self relieving seats

- Easy access to Gland Nut for packing adjustments

- Seal welded body

- Dual packing

- Extended bonnets as required

- Customized end connection

- Bi-directional seating

Advantages of Instrumentation Ball Valves:

- Tight shut-off capability

- Resilient seats provide bubble tight shut-off

- Position Indication

- Oval handle provides visual indication when valve is open and closed

- 1/4 Turn Operation

- Ball valves are able to operate very quickly

Applications

- Can be used as process valve applications – small and all welded design

- Steam condensate

- Gauge isolation

- Sampling valves

- Boiler blow down

- Breathers and drains

- Vent valves

- Root valves

Special Service

- Oxygen service

- Vacuum service

- HF Service

- Thermal fluids

- Steam

- Category “M” Services

- High temperature using metal seats

- Cryogenic Services

- Low Emissions services with FE bonnet

- Chlorine & Phosgene Services

Validation Testing

- Hydro-static Pressure Test to verify valves meet requirements of API

- Seat capacity rating test to obtain the max pressure rating of a specific seat material

- Life cycle test to obtain the number of open-close cycles prior to valve fail

- Seat pressure relief test to determine valve relief pressure

- Anti-static Test to prevent the build-up of potentially hazardous static charge on valve parts used for certain media

- Stem/Drive Train Deflection test to determine stem/drive train torsion strength in accordance with API

- Gland flange bolt torque and yield test to determine minimum bolt torque to seal stem packing and max bolt torque at which gland flange yields

- Fire test to verify functionality of valve fire lip in accordance with API 607 2016

- Fugitive emissions test to determine leakage at stem packing after cycling and at elevated temperatures

- Weld procedure to verify weld integrity via liquid penetrant test and nitrogen gas shell test

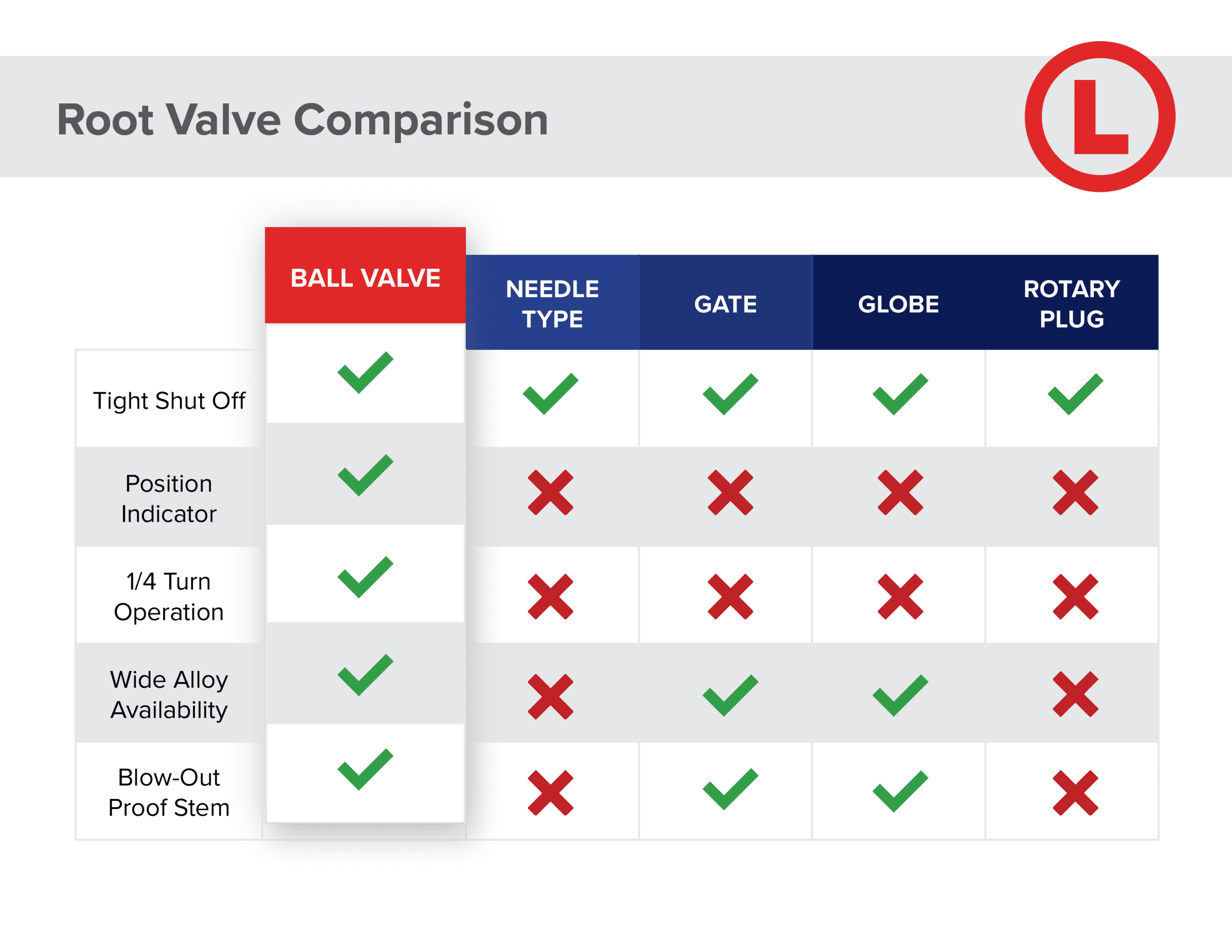

Competitor comparison:

Once again, Ladish will continue To Mark Progress.

We’re Social @LadishValves